360° Laser Profilometer for Tube Defect Detection

There are many industries that need to detect or measure possible defects. For example plastic fuel lines cannot have defects because it could indicate a possible leak, size defect or cosmetic imperfection. Another example would be ceramic coatings on cylindrical parts.

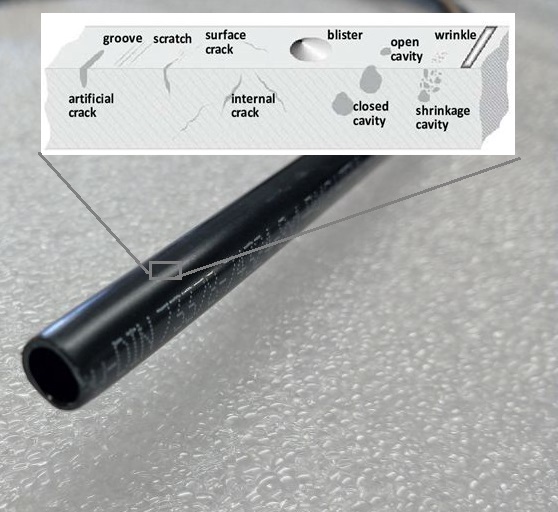

There are many types of defects possible such as cracks, scratches, blisters, cavities and wrinkles.

Optical Camera versus Laser Profiler

Optical cameras are good at taking pictures that show shape or color differences in 2D. Laser Profilers can be used to detect the z-height differences. For example tube surfaces are suppose to be round and smooth. Any difference from a smooth surface could be used to reject a bad part.

Application:

360 Laser Profilers for Tube Defect Detection

There are two ways to detect defects. The first is to hire workers to visually inspect each part. The second method is to buy automated system like this 360 tube laser profiler.

For high speed defect detection the tool could be setup to look for changes from the specification dimensions. If the diameter is too large or too small then a sensor could signal an alarm, save an image of the defect and then reject the part.

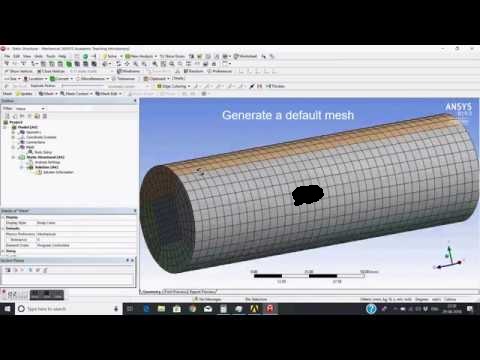

During normal speed defect detection the tool could record the profiles into file. The profiles can be added together to construct a 3D mesh image that could be viewed in Solidworks Viewer or other 3D rendering software.

Video of 360 Degree Laser Profilometer

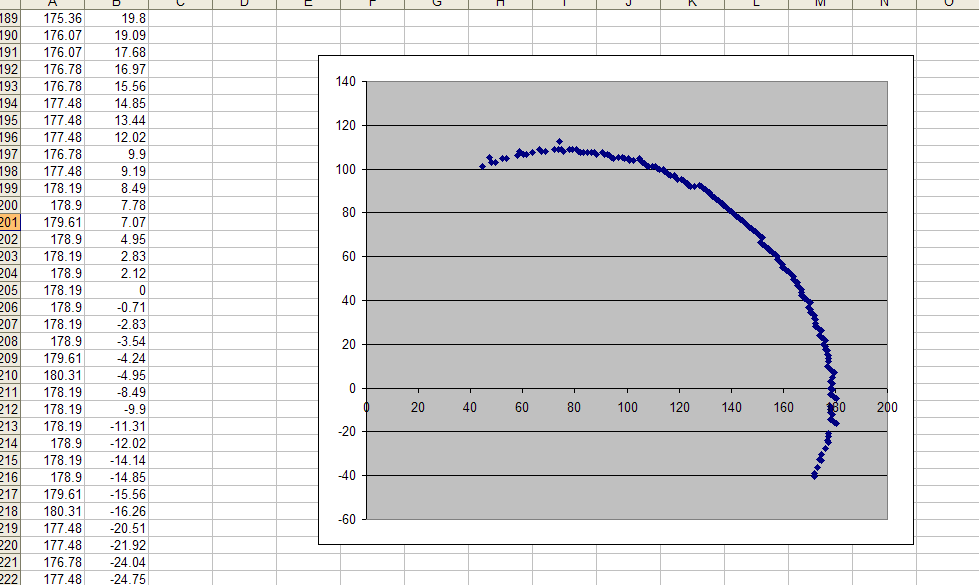

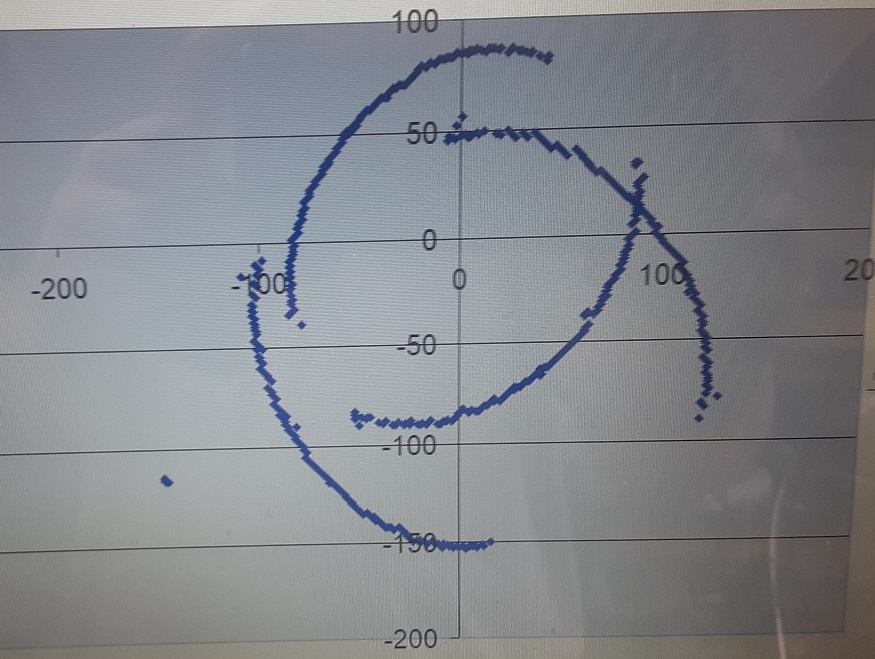

This videos shows how the 360 degree laser profilometer can be used to capture a profile and then visualize it with a spread sheet graphing program like MS-Excel.

4 laser profilers shown together

(More cameras are possible for larger diameter parts)

Contact Us

SMS Text Message